surface grinding machine parts

A grinding machine often shortened to grinder is one of the power tools or machine tools used for grinding it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation.

My4080 Hydraulic Surface Grinding Machine Hydraulic Surface Grindingmachine The Structure Of The Machine Tool Is Grinding Machine Hydraulic Machining Metal

A one stop Machine Shop for machining manufacturing.

. You pay 0 for repairs parts labor and shipping included. Each machine goes through a series of approvals tolerance checks and cycle checks before it. Production CNC Centerless Grinders.

Whether you are looking for concrete or asphalt road milling machine RMM can handle all your milling needs. The ACC-SA1 series MDI-controlled saddle-type surface and ACC-3280CHiQ surface double column grinder in particular are said to be well suited for shops. Withers Tool offers large part machining capabilities in grinding milling boring lathe services.

We have total 3 nos of Alex surface grinder machine RH500 in operation. 12 x 28Longitudinal maximum travel hyd. We are getting required accuracy after so many years operations.

In a grinding machine there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley. Drops spills and cracked screens due to normal use covered for portable products and power surges covered from day one. Shop by department purchase cars fashion apparel collectibles sporting goods cameras baby items and everything else on eBay the worlds online marketplace.

Since 1947 Insaco has been high-precision machining and polishing technical. Plan starts on the date of purchase. So when we start the electric motor the motor rotates at a certain rpm 150-15000 RPM it may change according to the types of.

Our road milling machine for sale comes in different sizes to address various industry needs. Insacos typical applications and a history of case studies to help with your next design. After sales service support is good.

The working principle of a grinding machine is quite easier to understand. Take a stroll down memory lane and learn the past of Insaco. The ACC-SA1 series MDI-controlled saddle-type surface and ACC-3280CHiQ surface double column grinder in particular are said to be well suited for shops.

Grinding is used to finish workpieces that must show high surface quality eg low surface. Our high quality and competitively priced machine parts will get your cafe back to running like clockwork in a heartbeat. Whereas in Todays article we.

There are various kinds of cutting fluids which include oils oil-water emulsions pastes gels aerosols mists and air or other gasesCutting fluids are made from petroleum distillates animal fats plant oils water and air or other raw ingredients. This collection contains those parts that need to be maintained and replaced at semi-regular intervals such as spouts filter baskets and shower screens. In the last article we had discussed the Drilling Machine Surface Grinding Machine Milling Machine lathe machine etc.

Clausing is dedicated to the highest standards in machine tool distribution and support services. With over 50 years of combined experience and a wide range of machine models Apex provides innovative all-in-one deburring and finishing equipment tailored to your application production level and budget. Deburring edge rounding slag grinding dross removal and straight grain finishing - all in a single pass.

Established in 1973 Micromatic Grinding Technologies Pvt Ltd MGT today manufactures a wide range of External Internal Universal and special purpose cylindrical grinders in CNC PLC and Hydraulic versions to the exacting requirements of our customers from its 3 plants in Ghaziabad near New Delhi. In a lathe machine every individual part performs an important task. On its surface grinding seems simple.

We recently procured the spare parts was delivered right on time and quality is good. 30Longitudinal maximum travel. Buy machinery and equipment from leading dealers across America.

At RMM we also manufacture high quality wear parts for all our soil stabilizer equipment and pavement milling machines. Our collection also includes all of the coffee shop essential accessories. A machine takes a rotating tool usually a wheel with abrasive grains and applies it to a workpieces surface to remove material.

Parts that require superfinishing include. See properties of materials we commonly machine. ACC-3280CHiQ is designed for high-precision grinding of large components including molds 40 x 40 and up to meet demanding mold and die base applications.

Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes such as machining and stamping. Leading grinding machine manufacturers around the world rely on JTEKT grinding machine tools and apparatus for high-tolerance precision grinding. Main Parts of lathe Machine.

A machine tool is a machine for handling or machining metal or other rigid materials usually by cutting boring grinding shearing or other forms of deformationsMachine tools employ some sort of tool that does the cutting or shaping. Working principle of Grinding Machine. For 3-year terms which are renewable.

Main Parts of Lathe Machine. A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish correct size and accurate shape of the workpiece. We have surveyed the global machine tool industry to identify and secure machine tools meeting our exacting quality standards for sales and distribution.

Each grain is its own miniature cutting tool and as grains dull they tear from the tool and make new sharp grains prominent. ACC-3280CHiQ is designed for high-precision grinding of large components including molds 40 x 40 and up to meet demanding mold and die base applications. Some important parts of a lathe machine are as follows.

Using high-quality materials and tooling we custom engineer our surface grinders to meet your mass production specifications. Since 1911 Clausing Industrial been providing machine tool excellence for American Industry. Automatic HydraulicDrive type.

A grinding machine often shortened to grinder is a power tool or machine tool used for grindingIt is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. The Institute comprises 33 Full and 13 Associate Members with 12 Affiliate Members from departments within the University of Cape Town and 12 Adjunct Members based nationally or internationally. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine.

Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff andor postgraduate students may work within the IDM. Definition Diagram Parts Working Advantages Disadvantages and Applications PDF Drilling Machine is used to make circular holes on the components with the help of Drill bits. We are using Alex machines from past 26 years for grinding to our products.

M820 Manual Surface Grinding Machine Grinding Machine Grind Hydraulic Systems

Http Blacksmithandmachineshop Com Images No 2 Hand Surface Grinder Ca 1880s Brown Sharpe 1895 Catalog Oneeighthpage 400 D Antique Tools Machine Tools Grinder

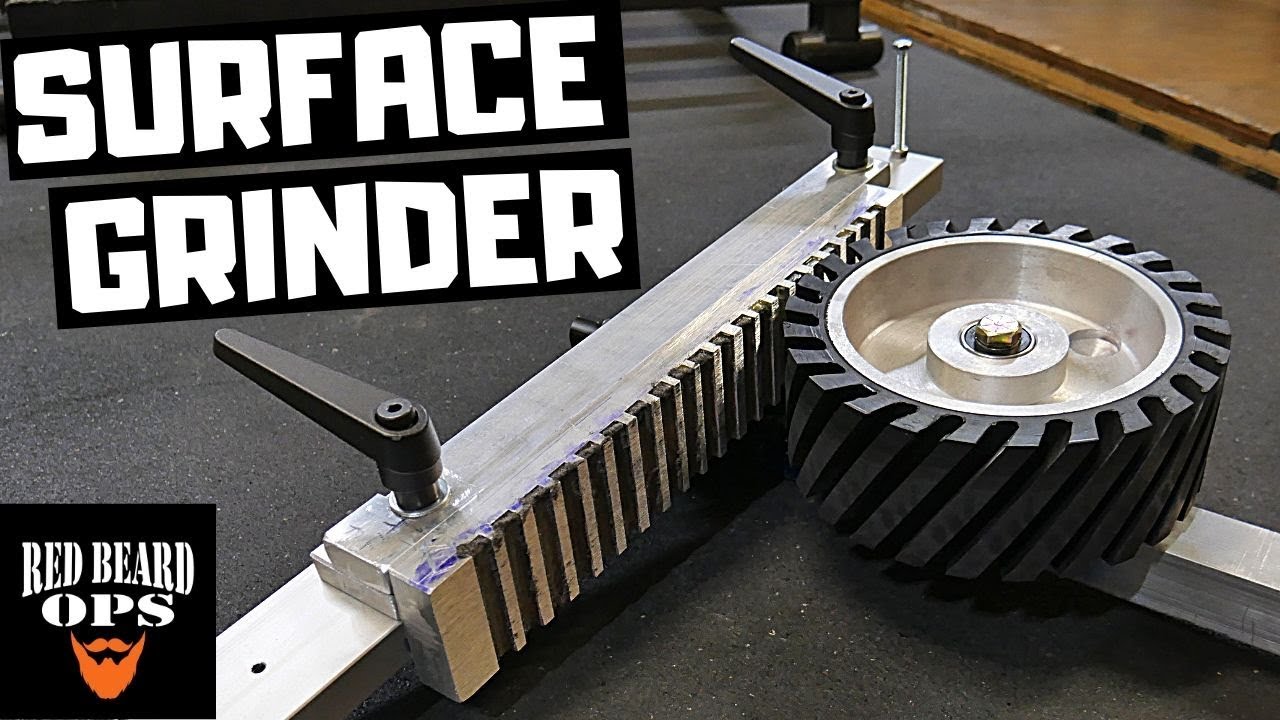

Diy Surface Grinder For Making Precision Parts At Home Machining Metal Projects Metal Working Tools Diy Tools Metal

Surface Grinding Or Sanding Part Of The Complete Online Guide To Knife Making Www Diyeasycrafts Com Knife Making Knife Sharpening Knife Making Tools

Slotting Machine It Is Used To Slot Materials Made Of Metal And Wood From Regular And Irregular Surfaces Both Checkout Machine Spare Parts Manufacturing

Surface Grinding Machines Grinding Machine Surface Manufacturing

3623 Saw Blade Sharpening Jig Blade Sharpening Cnc Parts Woodworking Projects

How To Further Improve The Machining Degree Of Surface Grinder Surface Improve Powder Metallurgy

Diy Surface Grinder For Making Precision Parts At Home Metal Working Machines Metal Working Grinder

There Are Grinders For Round Parts And Grinders For Flat Surfaces Those For Round Parts Include Machines Like Cylindri Grinding Machine Artistic Jewelry Tools

M7132 Hydraulicgrindingmachine The Screw Rod Of The Machine Tool Is Made Of Special Alloy Steel Through Strict Grinding Machine Hydraulic Non Ferrous Metals

Blanchard 11 Surface Grinder Parts Manual Ozark Tool Manuals Books Ozark Machine Shop Machine Tools

My1022 Hydraulicsurfacegrindingmachine Applicable To All Kinds Of Processing Machinery Auto Parts Fixture Magnetic Steel M Grinding Machine Machine Grind

Jones Shipman Type 540 Toolroom Surface Grinder Machine Shop Machine Tools Shipman

My1224 Hydraulicsurfacegrindingmachine Applicable To All Kinds Of Processing Machinery Auto Parts Fixture Grinding Machine Hydraulic Systems Machine Tools

Covel No 10h 618 Surface Grinder 6x18 Operator Parts Manual Ozark Tool Manuals Books

288 Homemade Surface Grinder Attachment Want Flat Things Youtube Belt Grinder Metal Bending Tools 2x72 Belt Grinder Plans